[ad_1]

Sizzling-wire foam cutters have lengthy been widespread within the crafting scene, however they are usually ignored by in the present day’s electronics-focused makers. I believe a part of the explanation for the oversight is that typical cheap foam cutters are supposed to be wielded by hand, so there is a component of ability and artistry to their utilization. Many manufacturers — together with myself — are much more comfy with computer-controlled fabrication strategies. When you’re like me, you might wish to try JP Gleyzes’s information to retrofitting basic MM2001 hot-wire foam cutter controller boards with FluidNC performance.

The MM2001 was a controller board launched within the ‘90s to be used with automated hot-wire foam reducing machines. It gave the impression to be hottest in France and would match most definitions of a CNC (computer-numerical management) machine controller. It could actually drive 4 unipolar stepper motors and the recent wire itself. However there are two huge caveats: it requires a parallel port connection and it doesn’t “converse” G-code.

These aren’t trivial issues, as a result of parallel ports are nearly extinct in the present day and nearly all CNC software program makes use of some number of G-code. Operating an MM2001-based machine in the present day would, subsequently, however very troublesome. That’s a disgrace, as a result of machines geared up with the MM2001 are very succesful due to these 4 stepper motors. JP Gleyzes got here up with an answer within the type of an adapter. It readily connects to trendy computer systems through USB and may learn normal G-code from no matter software program the person likes. It then spits out instructions that the MM2001 understands by means of the parallel port interface.

That “adapter” relies on an ESP32 improvement board. JP Gleyzes selected that as a result of they’re available, inexpensive, highly effective, and may benefit from FluidNC, which is CNC firmware developed particularly for ESP32 microcontrollers. Aside from some stage shifting between 5V and three.3V, the {hardware} connections are very easy. The MM2001 reads management indicators by means of the parallel interface pins, like route and steps for every motor, which the ESP32 offers by means of its GPIO pins. To keep away from messy wiring, JP Gleyzes designed a easy PCB “defend” that hosts the male parallel port connector and the ESP32 improvement board.

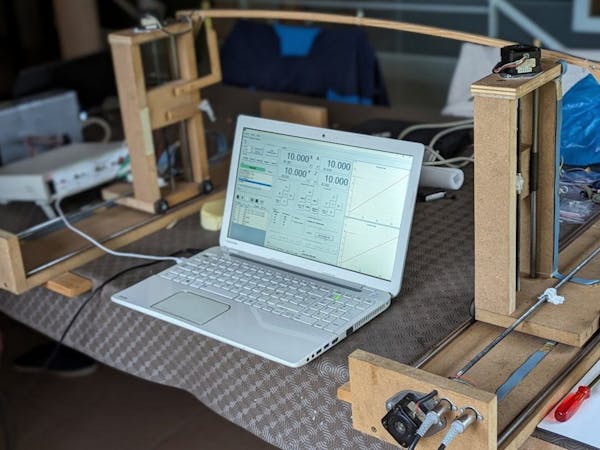

Now JP Gleyzes can simply use their MM2001 hot-wire foam cutter with a contemporary laptop computer and software program. It really works even higher than when it was new and the artistic potentialities are nearly countless.

[ad_2]