[ad_1]

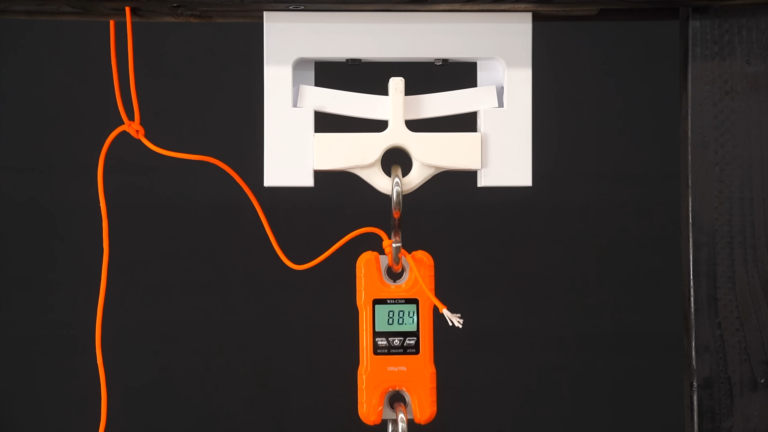

When working with an FDM 3D printer your first prints are possible trinkets the place energy is much less related than floor high quality. In a while when trying extra structural prints, the settings develop into crucial, and fairly frankly quite bewildering. Just a few makes an attempt have been made over time to find out in quantifiable phrases, how these settings have an effect on outcomes and right here is one other such experiment, this time from Youtuber 3DPrinterAcademy trying particularly on the impact of wall rely, infill density and the infill sample upon the energy of a easy beam when subjected to a midpoint load.

When establishing a print, many individuals will keep on with the identical few profiles, with just a little selection in wall rely and infill density, however usually maintain issues constant. This works effectively, up to some extent, and that time is if you need to print one thing considerably totally different in measurement, construction or perform. The slicer software program is normally very useful in explaining the impact of tweaking the numbers upon how the print is shaped, however not too nice at explaining the results of this in actual life, since it could’t know your utility. So far as the slicer is worried your object is a form that will probably be become slices, inner areas, outlines and assist buildings. It doesn’t know whether or not you’re making a keyfob or a bearing holder, and can’t assist you to get the settings proper for every utility. Maybe upcoming AI functions will probably be skilled upon all these experimental outcomes and be fed again into the slicing software program, however for now, we’ll simply need to go along with expertise and experiment.

The video does an inexpensive job of figuring out the yield level for just a few values of the parameters of curiosity, however most attention-grabbing had been the figures for which infill patterns are strongest, and easy methods to optimise for weight-to-strength ratio, which may very well be helpful for some of us.

This type of content material just isn’t new on these pages. Right here’s an experiment to find out the stiffness of varied filaments. Right here’s one other angle that makes use of printed worm gears as a testbed to find out the impact of printing orientation, amongst different components. If you happen to’re a bit newer to 3D printering than all this, then take a look at our information to getting began, full with precise sensible recommendation. That’ll by no means catch on.

[ad_2]