| Nov 03, 2023 |

|

|

|

(Nanowerk Information) Lithium-ion batteries powered the machine on which these phrases seem. From telephones and laptops to electrical automobiles, lithium-ion batteries are crucial to the expertise of the trendy world — however they will additionally explode. Comprising negatively and positively charged electrodes and an electrolyte to move ions throughout the divide, lithium-ion batteries are solely pretty much as good as the restrictions of their parts. Liquid electrolytes are probably unstable at excessive temperatures, and their effectivity could be restricted by nonuniformity and instabilities within the different parts.

|

|

Researchers are working towards growing safer, extra environment friendly batteries with stable electrolytes, a big change over the liquid model that presently transports ions in most commercially out there batteries now. The problem is that every solid-state materials has as many drawbacks as benefits, based on a crew primarily based on the Shenzhen All-Strong-State Lithium Battery Electrolyte Engineering Analysis Heart in Tsinghua Shenzhen Worldwide Graduate College’s Institute of Supplies Analysis.

|

|

To unravel this conundrum, the researchers mixed two of the prime solid-state candidates — ceramic and polymer — into a brand new composite electrolyte.

|

|

They revealed their leads to Power Supplies and Units (“Purposeful LiTaO3 filler with tandem conductivity and ferroelectricity for PVDF-based composite solid-state electrolyte”).

|

Key Takeaways

|

|

Standard solid-state battery parts face challenges like restricted conductivity and synthesis difficulties; the brand new composite goals to beat these.

Lithium tantalate used as a practical filler to enhance lithium-ion transport, overcoming resistance points on the polymer-ceramic interface.

The novel composite electrolyte demonstrates larger conductivity and an extended life cycle, even at low temperatures.

Findings recommend a promising path for solid-state lithium battery growth, with potential for improved efficiency and security.

|

|

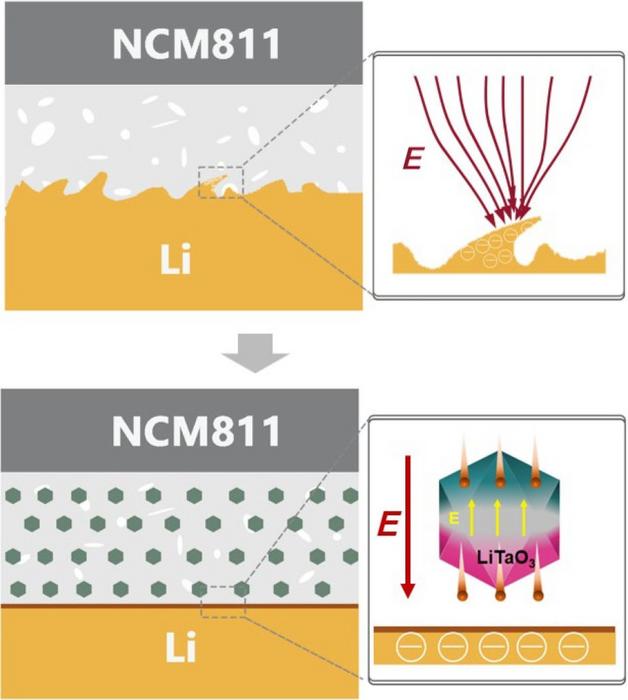

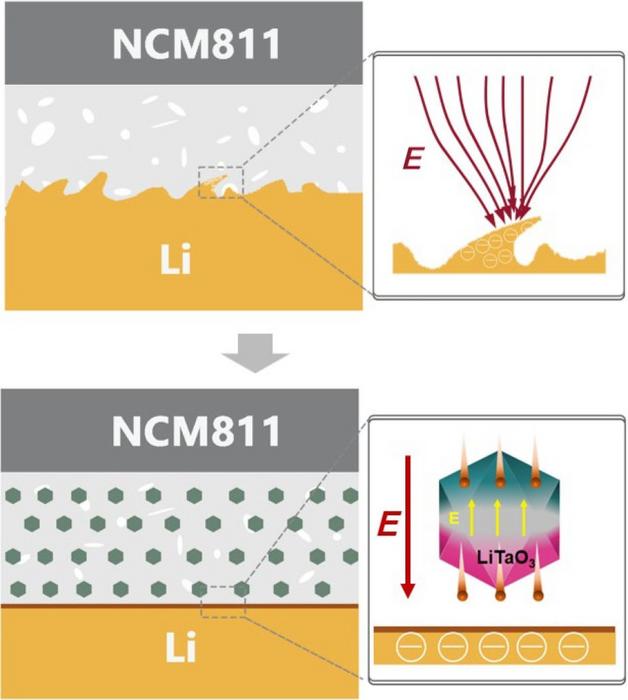

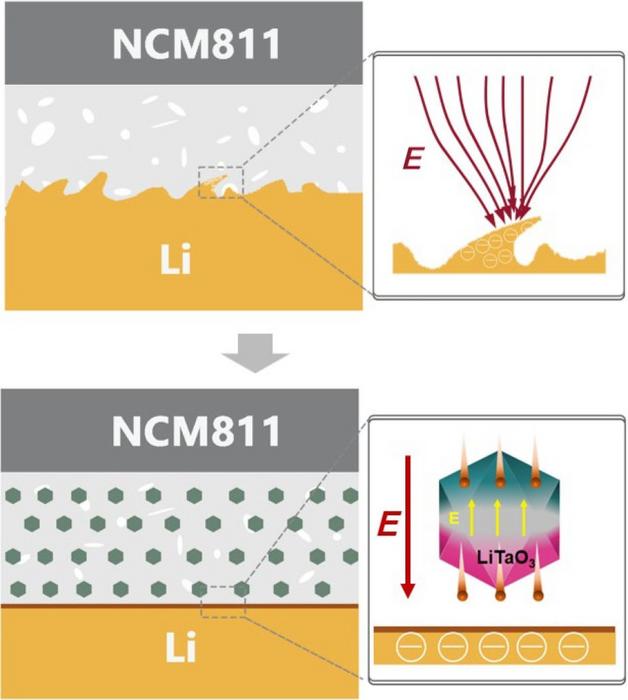

| A newly developed ceramic filler could assist alleviate limitations of composite solid-state electrolytes. The filler not solely mitigates interface obstacles between the composite parts, but it surely additionally offers an extra lithium-ion transport pathway, rising the variety of ions and the velocity with which they transfer via the electrolyte. (Picture: Power Supplies and Units, Tsinghua College Press)

|

The Analysis

|

|

“Composite solid-state electrolytes have acquired vital consideration resulting from their mixed benefits as inorganic and polymer electrolytes,” stated co-first writer Yu Yuan, who can be affiliated with Tsinghua Shenzhen Worldwide Graduate College. “Nevertheless, typical inorganic ceramic fillers provide restricted ion conductivity enhancement for composite solid-state electrolytes as a result of space-charge layer between the polymer matrix and ceramic part.”

|

|

Inorganic ceramic electrolytes provide excessive conductivity, however they develop resistance when confronted with one other stable and are difficult to synthesize. Polymer electrolytes are simpler to supply, extra versatile and work higher with electrodes, however their conductivity at room temperature is just too low for industrial software. In line with Yuan, combining the 2 ought to produce a extremely conductive, versatile electrolyte that’s simpler to synthesize. In actuality, nonetheless, when blended, the composite solid-state electrolytes have a separation — referred to as a space-charge layer — between their constituent elements that limits their conductivity.

|

|

To right this, the researchers used lithium tantalate, which has a crystalline construction that lends itself to distinctive optical and electrical properties, as a practical filler to mitigate the space-charge layer. The ceramic ion conductor materials is ferroelectric, imply it will possibly reverse electrical cost when a present is utilized.

|

|

“Not solely does the filler alleviate the space-charge layer, but it surely additionally offers an additional lithium-ion transport pathway,” stated co-first writer Likun Chen, who can be affiliated with Tsinghua Shenzhen Worldwide Graduate College.

|

|

The researchers experimentally demonstrated that the lithium tantalate filler eases the bottleneck for lithium-ion transport throughout the polymer-ceramic interface, leading to lithium ions transferring in each elevated numbers and velocity via the electrolyte.

|

|

The end result, the researchers stated, is an electrolyte with excessive conductivity and a long-cycling life — referring to how typically the ions could be transported throughout the battery in charging and discharging cycles — even at low temperatures.

|

|

“This work proposes a novel technique for designing built-in ceramic fillers with ferroelectric and ion-conductive properties to realize high-throughput lithium-ion transport of composite-solid electrolytes for advances solid-state lithium steel batteries,” Yuan stated. “Our method sheds mild on the design of practical ceramic fillers for composite solid-state electrolytes to successfully improve ion conductivity and battery efficiency.”

|