[ad_1]

In recent times, we have seen wooden used within the development of historically non-wooden issues like transistors, bicycles and drones. Now, scientists have used the stuff to create a robotic gripper … which undoubtedly has its promoting factors.

Ordinarily, robotic designers have to decide on between both gentle rubber grippers or ones fabricated from laborious metallic. The previous are good at greedy fragile objects with out breaking them, however will soften if subjected to excessive temperatures. The latter are far more heat-tolerant, however haven’t got a very gentle contact.

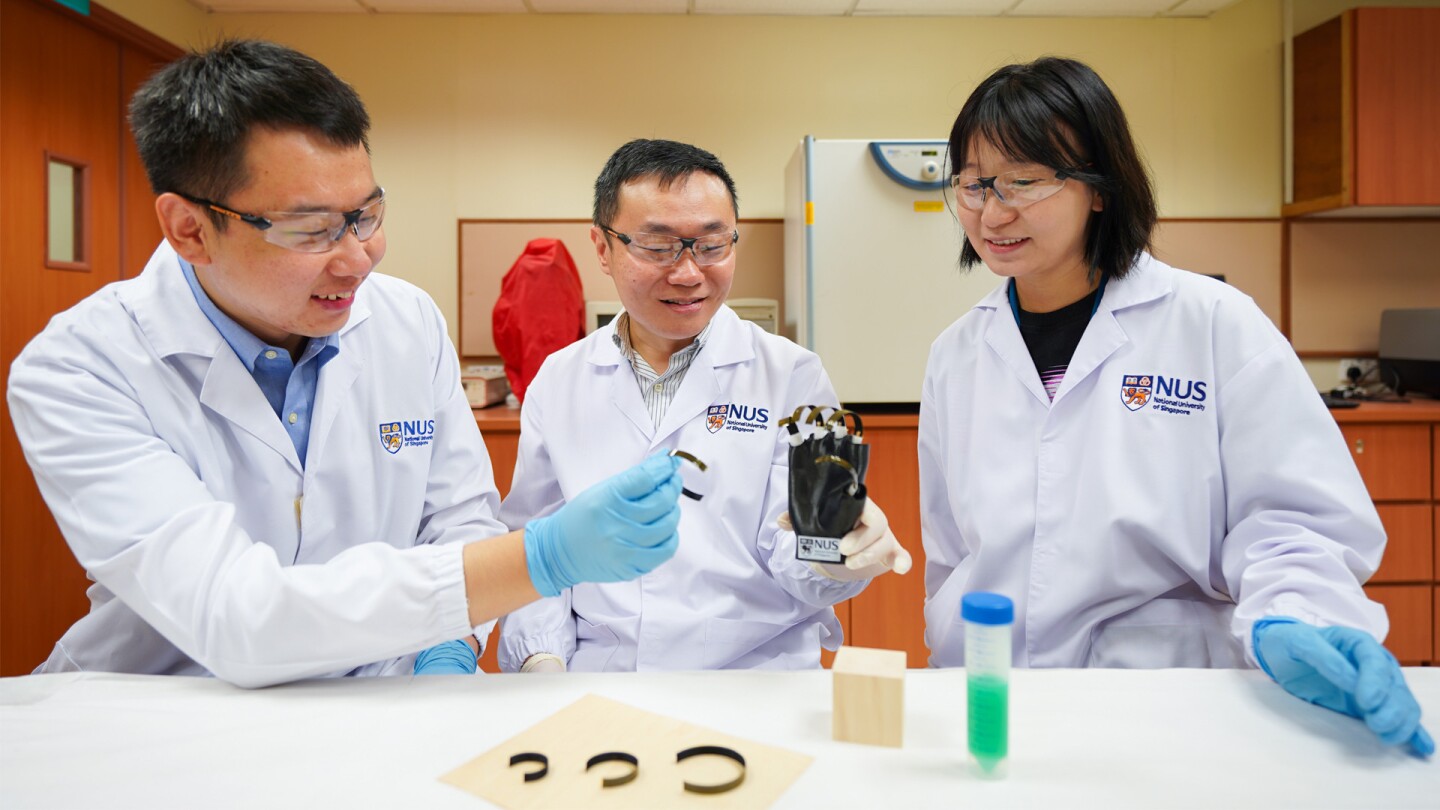

Led by Asst. Prof. Tan Swee Ching, researchers on the Nationwide College of Singapore teamed up with colleagues from China’s Northeast Forest College to mix the perfect options of each – utilizing wooden.

The scientists began with 0.5-mm-thick strips of Canadian maple, which they handled with sodium chloride to take away all of the lignin (an natural polymer which makes up a lot of wooden’s cell partitions). They then crammed the pores left by the lacking lignin with a polymer referred to as polypyrrole, which is sweet at absorbing warmth and light-weight.

Subsequent, a layer of nickel-based water-vapor-absorbing gel was utilized to at least one facet of every strip, whereas a hydrophobic (water-repelling) movie was utilized to the opposite. Lastly, the strips had been positioned in heated molds and formed into curved “fingers.” These fingers had been then built-in right into a robotic hand, aka a gripper.

When the appendages had been positioned in an setting with a relative humidity of 95%, the gel on their underside expanded because it absorbed water vapor, inflicting them to bend outwards.

After they had been positioned in an setting heated to over 70 ºC (158 ºF), nevertheless, water evaporated from the gel – this induced it to shrink, in flip inflicting the fingers to shut inwards. Likewise, when the gel was heated by publicity to a powerful gentle supply, it shrank and induced the fingers to shut.

Nationwide College of Singapore

Though the appendages would presumably catch fireplace at some level, they had been in a position to carry a 200-gram (7-oz) weight at an ambient temperature of 170 ºC (338 ºF) with out burning.

“Our picket robotic gripper can spontaneously stretch and bend itself in response to moisture, thermal and light-weight stimulation,” mentioned Ching. “It additionally has good mechanical properties, in a position to carry out complicated deformation, extensive working temperature vary, low manufacturing value, and is biocompatible. These distinctive options set it other than typical alternate options.”

After all, one would possibly surprise how the gripper might be made to open and shut on command, as a substitute of simply uncontrollably reacting to its setting.

“Greedy and releasing of the picket robotic grippers could be achieved by designing some gadgets and auxiliary gear,” Ching advised us. “For instance, some wires could be added to the wooden to finish the bending actuation below an exterior voltage to warmth up the wires; or a heating plate could be positioned close to the wooden gripper to drive it to bend; a laser/incandescent lamp can be used to irradiate the wooden floor to create warmth to regulate the bending and greedy; we are able to additionally spray water round/on the floor of the wooden in order that it stretches out for releasing the thing.”

The analysis is described in a paper that was revealed within the journal Superior Supplies.

Supply: Nationwide College of Singapore

[ad_2]